PCB Requirements-Gerber File

Gerber File – Requirements for Generation and Fabrication

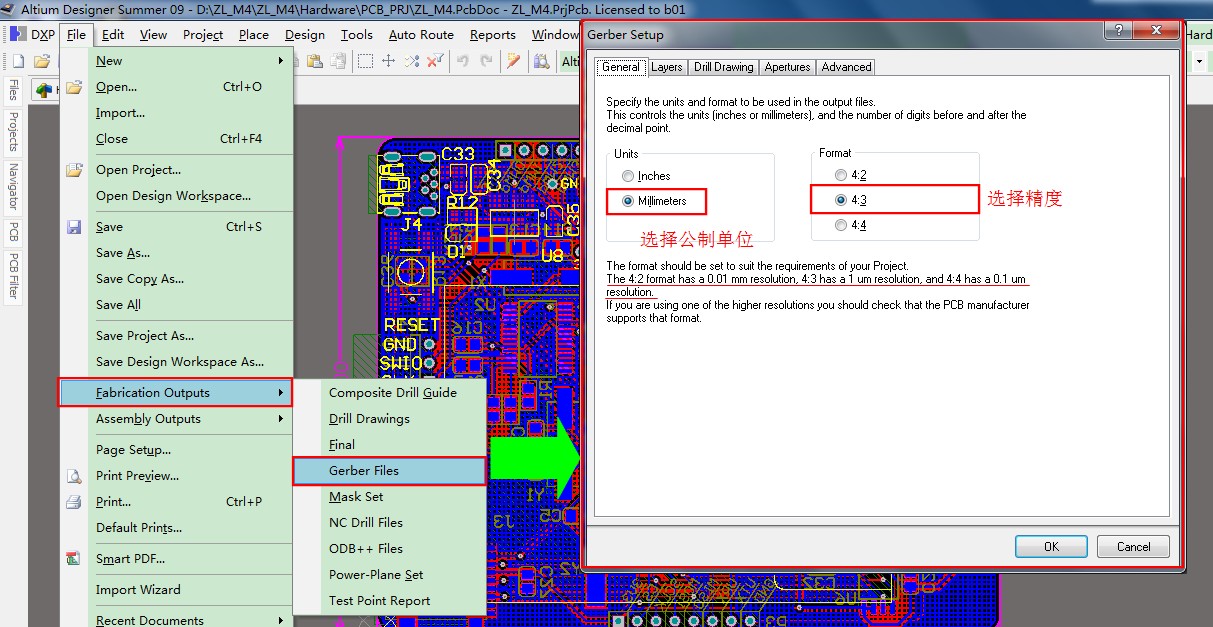

File Generation

You will need a Gerber image file for each of the conductor layers, solder mask layers and legend layers. We suggest that even if the solder mask images are the same for both sides that you submit a file for each anyway. While we can accept these files in many formats the preferred format is 274-x with 4 digits after the decimal point (typically represented as 274-x 2.4). If your software does not have the capability to output the 274-x format you will need to use 274-d, this will require the image files as well as the aperture report (please generate one comprehensive aperture report that can be used for all files).

You will need a Gerber image file for each of the conductor layers, solder mask layers and legend layers. We suggest that even if the solder mask images are the same for both sides that you submit a file for each anyway. While we can accept these files in many formats the preferred format is 274-x with 4 digits after the decimal point (typically represented as 274-x 2.4). If your software does not have the capability to output the 274-x format you will need to use 274-d, this will require the image files as well as the aperture report (please generate one comprehensive aperture report that can be used for all files).

If you have the option to set the position of the image on the film please set this to lower left corner. It is also preferred to have the board outline in the solder mask images and drill drawings only.

We will view the files from the “Component” side looking down, through the printed circuit board. “Solder” side is ALWAYS on bottom. Including your part number and/or company name on copper layers (Right-Reading from the respective side of the board).And prevents your board from being build inverted (Top on Bottom, Bottom on Top).

Fabrication Print / Drill Drawing

It is a great idea to submit a Fabrication Print / Drill Drawing with every design package. It is best if this is supplied as a Gerber file, but we can accept this as a PDF or DXF. This print should include a dimensioned board outline, graphic representation of hole locations with legend identify finished hole size, and pertinent fabrication notes. When providing fab notes, limit the number of notes per board to as few as possible, and avoid the temptation to cut and paste notes from a previous design. While it saves time, you may end up including notes that aren’t applicable to your design, increasing the chances that notes specific to your design may get lost in the shuffle. Take advantage of the existing industry standards. A good example of this is IPC-6012, which addresses almost all requirements pertinent to the performance and appearance of most commercial rigid boards. It’s much simpler, and infinitely more useful to the manufacturer, to simply refer to the IPC specification to which you want the board built. Instead of detailed descriptions, which are open to interpretation by the manufacturer, specify “Build to IPC-6012, Class 2.” (A complete listing of the specs can be found at ipc.org.)

NC Drill File

An Excellon format NC drill file will need to be provided as well. We prefer 2.4 trailing format. We also accept the EIA, ASCII Odd formats. If possible please provide one files for both plated and non-plated holes. If a separate file must be created for the non-plated holes please be aware that these holes will not be taken into consideration during the FreeDFM analysis.

Read me Text File

Please include a “Read.Me” text file (ASCII text information file) that contains the following information:

- List of every file name with a brief description as to what it is.

- List all non-Gerber specs for this job, if not included in a fab.

- Print your contact information (include evening phone if you like).